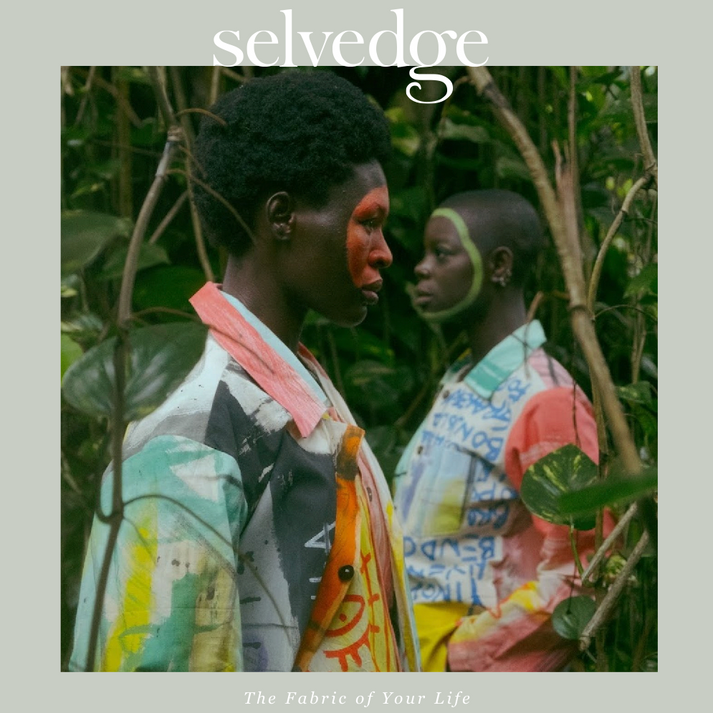

Selvedge Magazine

Selvedge Magazine - Issue 111 Make Do

Selvedge Magazine - Issue 111 Make Do

Couldn't load pickup availability

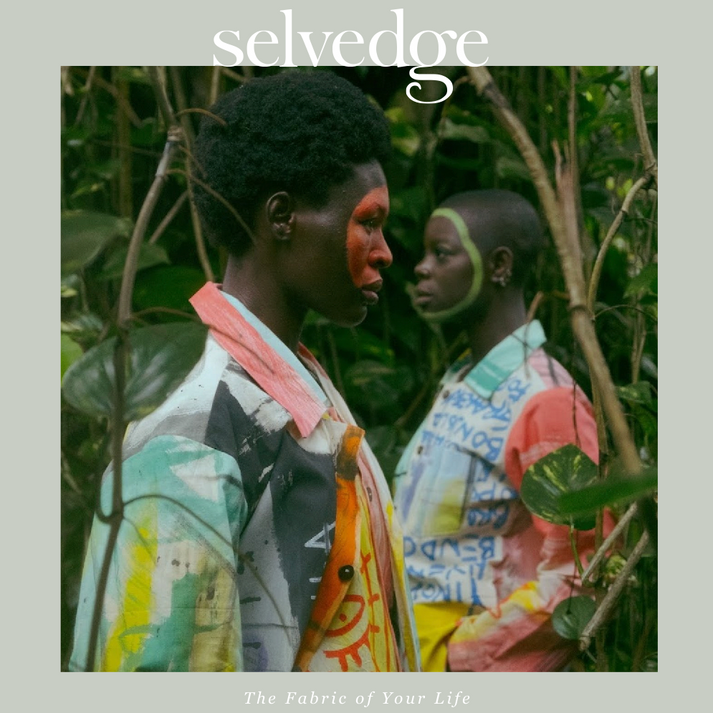

Of the 100 billion garments (92 million tonnes) produced each year, 62 per cent end up in landfill. It is therefore increasingly difficult for makers to justify the use of virgin cloth and many are now looking to creative recycling as a way of sustaining their practice. Recycling is nothing new. In the issue, we explore the market for second-hand clothes at Harvard University in the 1850s, the endeavours on both sides of the pond during the depression of the 1930s, and the shortages imposed by rationing during the Second World War when necessity truly was the mother of invention.

Bringing us up to date, Chrispina Ffrench explained to us that the design process involved in reusing fabrics is challenging by its limitations. There are fewer options, but more creative choices are required at each step of production requiring makers to use judgment. This can enhance the connection between maker and product, and result in a sense of pride which in turn enhances the quality of life.

Upcycling lacks the standard and predictable aesthetic of new and holds stories, history, and meaning, but is not an inexpensive way to work. Most upcycled materials are inconsistent in terms of colour, quality, size, etc; even when purchased in volume, all aspects of costing, therefore, are inconsistent meaning that the law of averages plays a starring role. When a company manufactures jeans using yardage, costs are straightforward. The variable cost in this production model lands squarely in workforce productivity. Things like shop layout, stellar management, employee morale, and reasonable expectations help with efficiency in this setting. When a company is manufacturing jeans from patches of other jeans that have passed their wearable lifespan, costing requires that an average cost of materials is found. Finding that average is a complex equation taking things like cleaning, fabric quality and consistency and size into consideration, and this is just the back end.

Designing with recycled materials is a whole other can of worms. Running production with upcycled clothing, manufacturers’ waste or deadstock as raw material sets a challenge of its own. When designing with post-consumer clothing it is cost-effective and fun to use original details in fresh ways. Rather than creating a button placket, repurpose one from a garment you are no longer able to use. You can use shoulder seams as shoulder seams, pockets can be carefully harvested and incorporated. Cuffs make great cuffs. Part of the delight found while upcycling textiles comes from ascertaining which elements of a discarded garment still have integrity and can be given a new life and which parts are worn out. What can be created with worn-out elements?

We predict that this trend will run and run and see it not only in contemporary works such as Jenni Stuart-Anderson's ‘Global Warming’ rug commissioned to promote Greta Thunberg’s ‘The Climate Book’ but also in the collections of fashion designers from Grey Lauren and Alexander McQueen to Elizabeth Wilson, who has been repurposing antique kimono fabrics sourced in Japan into stylish contemporary garments for 45 years. All of these designers make good use of an aesthetic based on using craft skills to combine small elements of repurposed fabrics to create rich new multi-textured and multi-coloured surfaces. Find out more about recycling at Crispina Ffrench’s virtual summit ‘Rags to Riches’ on 12-14 April 2023. See you there.

Materials

Materials

Dimensions

Dimensions

Care information

Care information